Since 2003, UAB STEVILA has been working in accordance with DIN ISO 9001 quality management standard. The internal and external audits that are performed on a yearly basis document the continuous process of the company improvement and motivate the employees to go to higher goals.

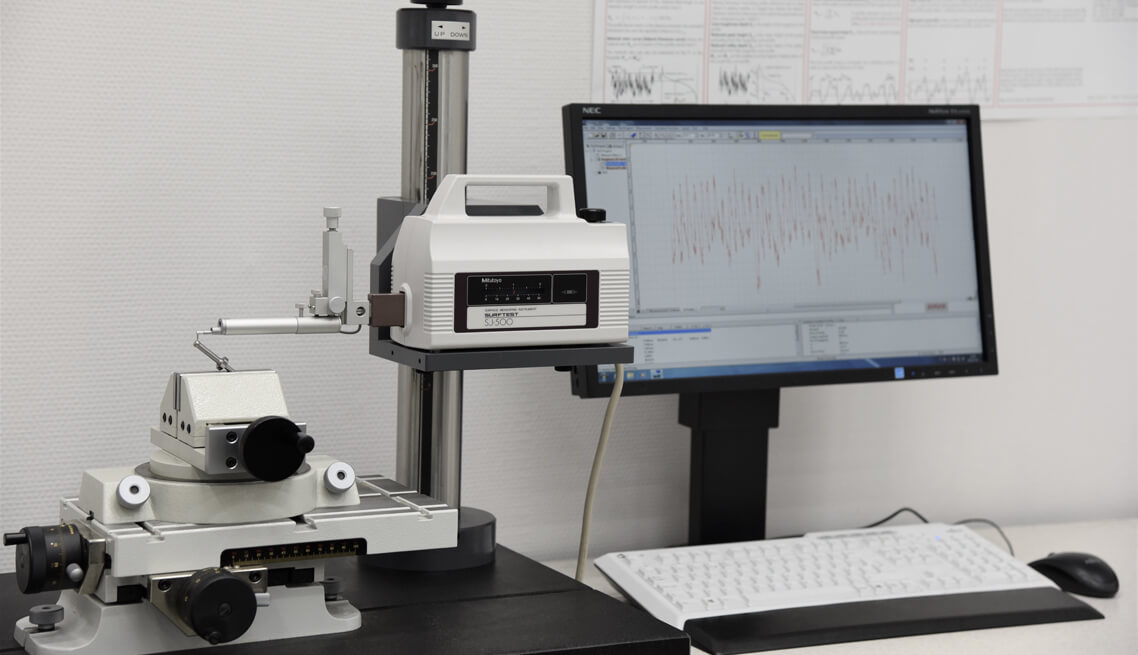

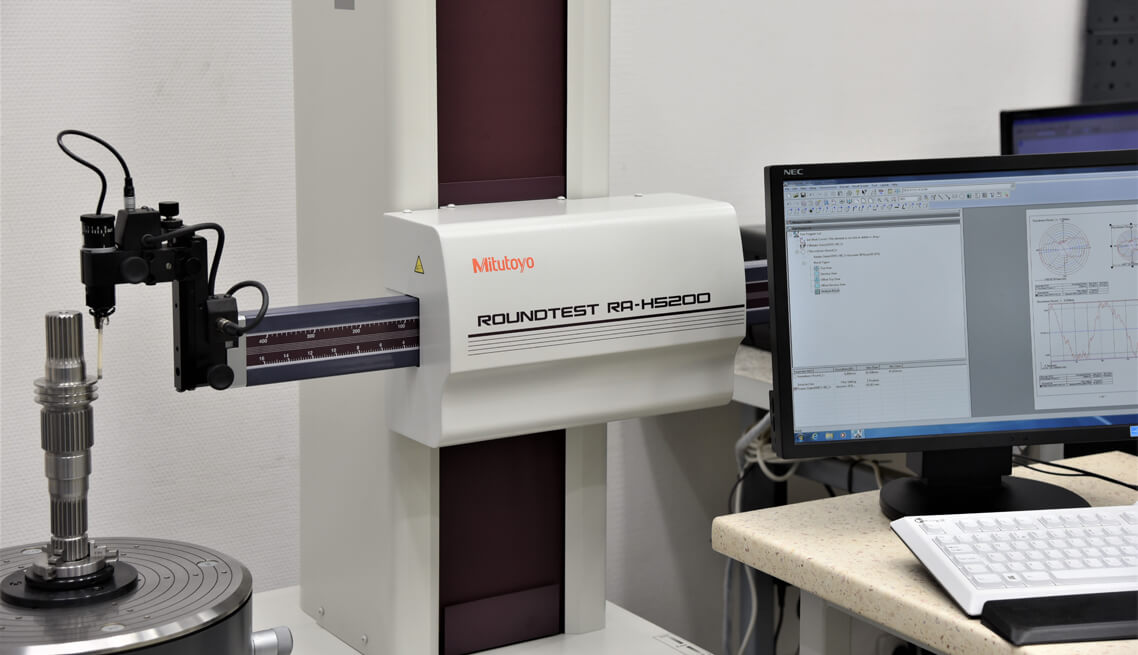

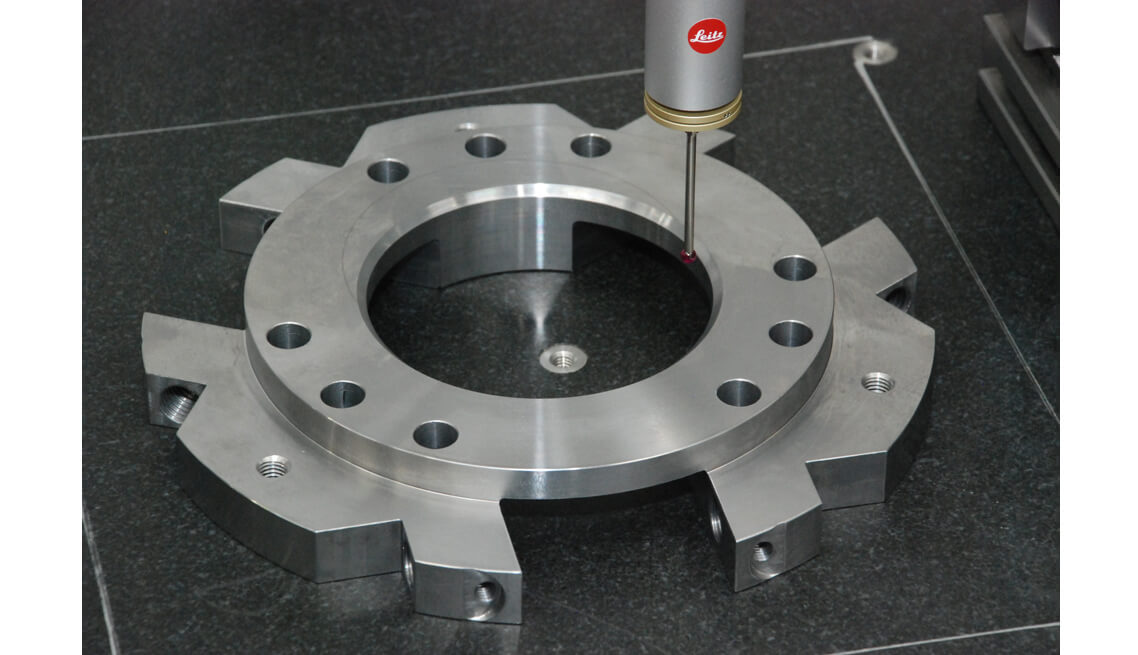

In pursuance of its quality policy and with the help of modern technical mechanisms and innovations, UAB STEVILA produces high quality products that fulfill the needs and expectations of the customers. Regular professional trainings of the employees ensure responsibility of every employee for the product and workmanship quality.

Delivering products of required quality is one of the main KPI’s.

Target for 2024: < 1500 ppm